A German Dental Products Manufacturer Chooses Dental Fast Sintering Furnaces for Rapid Sintering of Ceramic Crowns

One German dental products manufacturer recently sought to improve the

efficiency of its ceramic crown production to meet a growing demand for

high-quality, fast-turnaround dental restorations.

After an extensive review of available technologies, the company selected Brother Furnace’s dental fast sintering furnace for its unique ability to accelerate sintering processes while ensuring the durability and aesthetics that patients and professionals expect.

As a manufacturer specializing in high-performance dental sintering solutions, our commitment to advancing dental restoration technologies has made us a trusted choice for dental professionals worldwide.

This case study provides an in-depth look at how this German manufacturer

integrated our dental fast sintering furnace into their workflow, the tangible

benefits they experienced, and their feedback on the product's impact on their

operations.

Customer Background

The German dental products manufacturer, established over one decade ago, has built a reputation for excellence in crafting reliable and precise dental tools, systems, and materials. With a focus on dental implants, crowns, and bridges, the company has consistently sought innovative methods to enhance productivity without compromising quality.

As demand for dental ceramics surged, the company’s management team recognized the need to adopt a more efficient and precise sintering process. Traditional sintering methods, while effective, required several hours per cycle, making it challenging to keep up with a high volume of orders, especially for time-sensitive dental restorations.

To modernize its sintering process, the company conducted a search for a furnace that could deliver shorter sintering times, maintain material integrity, and consistently produce high-quality results. After comparing various sintering furnace options, they found the dental fast sintering furnace of Brother Furnace met and exceeded their expectations.

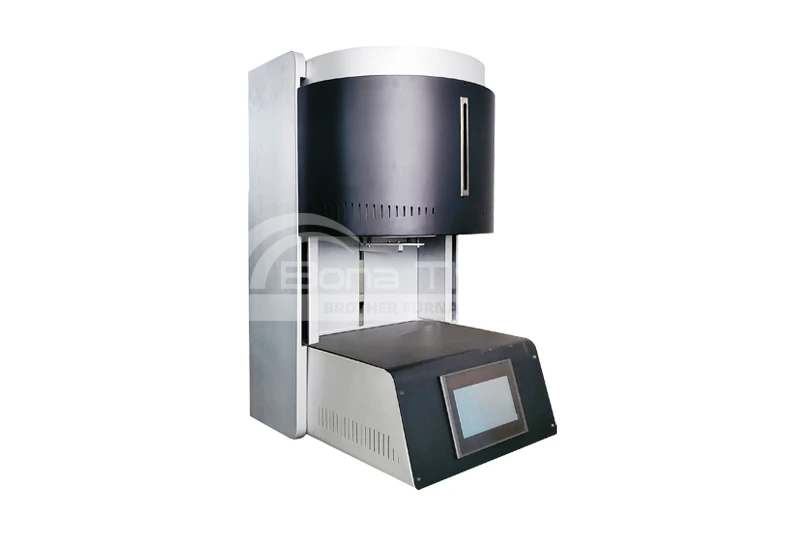

Product Overview: Dental Fast Sintering Furnace

The dental fast sintering furnace is designed with the needs of dental

laboratories and manufacturers in mind, specifically focusing on the high

demands of zirconia and ceramic sintering for dental restorations. With advanced

heating elements and precision-controlled temperature settings, our furnace

supports rapid sintering cycles while preserving the physical properties

required for long-lasting crowns and dental parts.

Key features include:

● Rapid Heating and Cooling Cycles: The furnace can achieve the desired sintering temperatures significantly faster than traditional models, reducing each cycle's time while maintaining thermal stability.

● Advanced Temperature Control: Built-in sensors ensure uniform heat distribution, critical for preventing cracks and inconsistencies in the sintered product.

● User-Friendly Interface: With an intuitive digital display and customizable settings, the furnace allows users to adapt cycles to specific material needs, making it versatile and straightforward for operators.

● Energy Efficiency: Our design optimizes power usage, which is essential for dental labs focused on both productivity and sustainability.

● Implementation and Initial Feedback: Upon installation of our dental fast sintering furnace, the German manufacturer observed an immediate improvement in their production times.

The first series of tests showed that sintering times for zirconia crowns

were reduced by nearly 30%, allowing the company to produce more units daily

without compromising the structural quality of the crowns. Additionally, the

user-friendly design allowed their technicians to easily adjust settings,

creating an adaptable workflow that met the specific needs of each product

batch.

One of the lead technicians expressed satisfaction with the furnace’s operational efficiency, noting, “The intuitive control panel and programmable cycles have simplified our production process significantly. Our team has seen a reduction in human error during setup and temperature adjustments, and the results have been outstanding. The crowns sintered in this furnace exhibit a smooth finish and remarkable strength.”

Customer Satisfaction and Quality Results

As the German company continued using our furnace, they reported sustained improvements in product quality and operational efficiency. Technicians highlighted the following benefits:

1. Consistent Quality: The crowns sintered in the dental fast sintering furnace demonstrated superior density and aesthetic quality, with natural translucency that matched customer expectations.

2. Faster Turnaround Times: By reducing sintering cycles, the company met tight deadlines with ease, giving them a competitive edge in an industry where delivery time is crucial.

3. Enhanced Workflow Efficiency: With shorter sintering times and minimal

downtime for cooling, the production line ran smoothly, reducing bottlenecks and

allowing the team to focus on other aspects of dental restoration.

Conclusion

Our partnership with this German dental products manufacturer exemplifies Brother Furnace’s role as a leading provider of advanced sintering solutions for the dental industry.

The dental fast sintering furnace has enabled the company to enhance its production capabilities, deliver high-quality ceramic crowns faster than ever before, and ultimately improve its competitive position in the market. This successful integration showcases the furnace's ability to meet the rigorous demands of modern dental manufacturing, setting a standard for rapid, reliable, and energy-efficient sintering.

For other dental labs and manufacturers seeking to optimize their workflows and improve product quality, our dental fast sintering furnace offers a compelling solution.

By choosing Bother Furnace, companies can achieve remarkable efficiency gains while maintaining the aesthetic and structural integrity essential for dental applications.

As a dedicated manufacturer of dental sintering furnaces, Brother Furnace

remains committed to supporting our clients with the highest standards in dental

manufacturing, from initial installation to ongoing support.

With every partnership, we reinforce our commitment to driving advancements in dental sintering technology, helping our clients remain at the forefront of innovation and quality.

If you also need a dental fast sintering furnace to optimize your experiments and production, please feel free to contact us. Brother Furnace will provide you with the best products and services.