From the Material to the Finished Product: How the Dental Porcelain Furnace Realizes Ceramic Dentures

In modern restorative dentistry, the production of ceramic dentures is a delicate and complex process in which dental furnaces play an indispensable role. As a professional manufacturer of dental porcelain furnaces, Brother Furnace understands the importance of a high-quality porcelain furnace to achieve ideal restorative results.

In this article, we will analyze the entire process of ceramic denture making, from the selection of materials to the final product, to help you to understand the keys to each step of the process.

What is a Dental Porcelain Furnace

A dental furnace is an indispensable piece of equipment in the dental laboratory, mainly used for heating and curing dental ceramic materials. By applying high temperatures, the furnace is able to achieve the desired physical and chemical properties of the ceramic material, ensuring that the resulting denture has the strength, aesthetics, and durability it needs.

With advanced technology and efficient performance, Brother Furnace's porcelain furnaces provide a reliable solution for the dental field.

Components of a Dental Porcelain Furnace

Brother Furnace's design of dental porcelain furnaces aims to ensure uniformity and stability of the heating process.

Chamber: This is the core part of the furnace and is responsible for providing a high-temperature environment to bake the ceramic material. The furnace chamber is usually made of high-temperature resistant materials that can withstand extreme temperatures without distortion or damage. The chamber of the Brother Furnace is made of high-quality quartz tubes to ensure uniformity and stability of heat transfer.

Temperature Control System: A precise temperature control system is essential to ensure quality in every bake. Dental porcelain furnaces monitor the temperature inside the furnace in real-time with built-in high-precision sensors to maintain a stable temperature. The Brother Furnace utilizes advanced digital temperature control technology that maintains consistency through small temperature fluctuations, resulting in a temperature difference of no more than one degree, providing perfect curing conditions for the ceramic material.

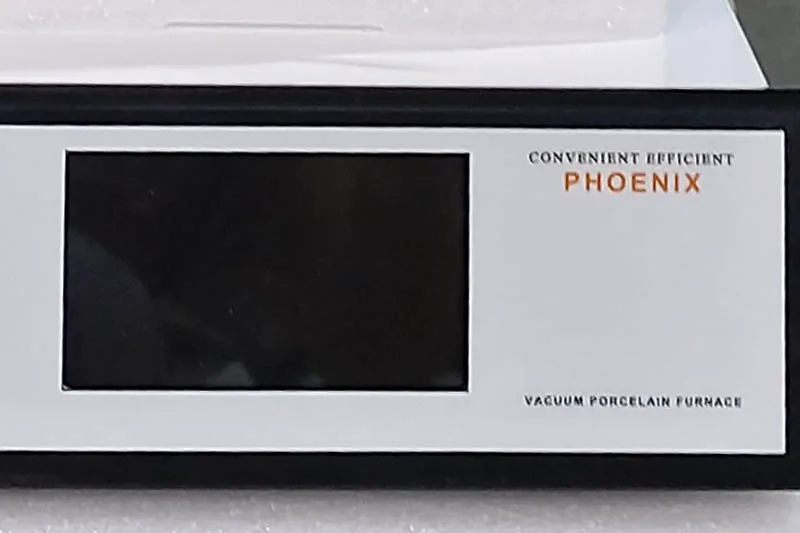

Operation Panel: Brother Furnace equips the porcelain ovens with a touch screen operation panel, through which you can set up the baking program, adjust the temperature and time, and other parameters. This panel is not only easy to operate but also powerful, allowing the customer to make precise settings according to different ceramic materials and denture types.

The porcelain furnaces manufactured by Brother Furnace have significant technological advantages. These technical advantages have led to porcelain furnaces being widely used and highly regarded in high-standard dental laboratories.

Preparation for Ceramic Denture Making

Before ceramic dentures are fabricated, a series of delicate preparations are required, including the selection of suitable ceramic materials, the design of the denture model, and the fabrication of molds. These preparations are essential to ensure the quality and effectiveness of the final product.

1. Selection of Ceramic Materials

The choice of ceramic material plays a decisive role in the quality and function of the denture. Different ceramic materials have different physical properties, such as hardness, strength, light transmission, and color stability. The selection of the right material needs to be based on the specific needs of the patient, the area of use of the denture, and the intended function.

For example, high-strength aluminum oxide ceramics are suitable for posterior restorations, while zirconium ceramics with excellent light transmission are more suitable for aesthetic restorations of anterior teeth. Brother Furnace is capable of handling various types of ceramic materials to meet different restorative needs.

2. Design of Denture Model

The design of the denture model is an important part of the final restorative effect. The designer needs to develop a model that meets the physiological and aesthetic requirements based on the patient's oral condition and tooth structure.

This process usually involves digital scanning, the use of CAD software, and close communication with the dentist. A highly accurate design ensures the comfort and functionality of the denture, thus enhancing the patient's experience.

3. Mold Making

After the design is completed, molds are made to facilitate the molding of the ceramic material. The molds are made with a high degree of precision to ensure that the size and shape of the denture are exactly as designed. Molds are usually made of high-strength materials such as casting alloys or silicone.

The Process of Porcelain Baking

The core of the work of a dental porcelain oven is the heating and curing of the ceramic material.

1. Pre-treatment of the Material

Before the ceramic material is placed in the oven, it needs to be pre-treated, including cleaning, drying, and preheating steps. These steps remove impurities and moisture from the surface of the material and prepare it for the subsequent heating process.

2. Heating Process

The heating process is the core of the porcelain furnace. Ceramic materials are usually subjected to a number of heating stages, the temperature and time settings of which are precisely adjusted to the material's characteristics and requirements. A typical heating process includes:

Preheating stage: The material is heated to a lower temperature to relieve the internal stresses of the material and allow it to gradually adapt to higher temperatures. Temperatures in this phase are usually between 500°C and 800°C, depending on the type of material and requirements.

Main heating stage: In this stage, the furnace temperature rises rapidly to the final temperature required for the material, typically above 1000°C. The temperature of the furnace is then increased to the final temperature of the material. The high temperatures allow the ceramic material to reach its optimum physical properties, including hardness and density. Brother Furnace's porcelain furnaces heat up quickly and uniformly, ensuring that every denture component meets predetermined performance standards.

Holding stage: After reaching the set final temperature, the material is held in this stage for a certain period of time to ensure that it is fully cured. The length of the holding time affects the final properties of the ceramic and usually ranges from a few minutes to several hours.

3. Cooling Process

After the porcelain furnace has finished heating, it needs to go through a cooling phase to gradually reduce the temperature inside the furnace to a safe level. The speed and homogeneity of the cooling have a significant influence on the final properties of the ceramic material. Rapid and uniform cooling can effectively avoid internal stresses and cracks in the material.

4. Subsequent Processing

After baking and cooling, the denture is usually subjected to subsequent processing, including surface polishing, inspection, and adjustment. These steps can further enhance the appearance and comfort of the denture and ensure that it fits perfectly into the patient's mouth.

Brother Furnace Looks Forward to Working with You!

Through a detailed analysis of the dental porcelain furnace in the ceramic denture-making process, we can see that the performance of the furnace has a direct impact on the quality of every step of the process. As a leading manufacturer of porcelain furnaces, Brother Furnace is committed to providing the best quality products and services to our customers.

Not only do Brother Furnace's dental porcelain ovens offer efficient heating and precise temperature control, they also provide an exceptional operating experience, making them the ideal solution for your dental lab.

Brother Furnace believes that as technology continues to advance, dental porcelain furnaces will play an increasingly important role in the fabrication of ceramic dentures.

Brother Furnace looks forward to contributing to the field of dentistry together with you and restoring patients' confident smiles.