Maximizing Precision in Dental Restorations: The Essential Role of Dental Porcelain Ovens

Dental porcelain ovens are a fundamental tool in modern dentistry,

specifically within dental laboratories, where their precision and reliability

are essential in creating dental restorations.

These high-tech devices, sometimes called dental porcelain furnaces or porcelain ovens for dental restorations, use controlled high temperatures to transform ceramic materials into durable and aesthetically pleasing crowns, bridges, veneers, and other restorations.

The essential function of dental porcelain ovens lies in their ability to manage the delicate balance of heat and pressure necessary to properly sinter, glaze, and stain ceramic dental materials. These processes, which include the dental ceramics firing process and sintering furnace operations for dental ceramics, are pivotal for creating restorations that blend naturally with a patient’s teeth, both in appearance and functionality.

Brother Furnace, as a leading manufacturer in the field, designs and supplies advanced ceramic furnaces for dental use to support dental labs worldwide, ensuring consistent quality and longevity in restorations.

In this article, we explore the vital uses of these ovens, their diverse

features, and how they serve as dental restoration equipment that elevates the

art and science of dental aesthetics.

Key Uses of Dental Porcelain Ovens

The role of dental porcelain ovens extends across multiple applications within dental restoration. Here’s a closer look at the primary functions they fulfill:

Fabrication of Dental Crowns and Bridges

Crowns and bridges are among the most common dental restorations created with dental porcelain furnaces. These restorations require strength and durability, qualities achieved through precise control of heat within the furnace. The firing process managed in all-ceramic furnaces, transforms raw porcelain material into a solid, lifelike restoration.

This step is essential in achieving a natural appearance and ensuring that the restoration can withstand regular dental functions.

Creation of Veneers and Inlays

Veneers and inlays demand an extra level of aesthetic appeal, as they enhance the front surfaces of teeth and are highly visible. Through the dental ceramics firing process in high-temperature dental ovens, these restorations receive a glossy finish that matches natural enamel. The oven’s ability to accurately control glaze and stain levels ensures that each veneer or inlay fits seamlessly within a patient’s smile.

Sintering of Zirconia Restorations

Zirconia, known for its high strength and durability, has become a popular

choice for dental restorations. However, it requires sintering at extremely high

temperatures to reach its optimal hardness and translucency. Sintering furnaces for dental ceramics provide the necessary high-temperature environment to

process zirconia effectively, making these ovens indispensable for laboratories

that work extensively with zirconia materials.

Firing Metal-Ceramic Restorations

Metal-ceramic restorations combine the strength of metal with the aesthetic appeal of ceramic. In these cases, metal-ceramic firing ovens are crucial for bonding ceramic to metal substrates, ensuring a durable and aesthetically pleasing result. This process requires careful control over both temperature and atmosphere to achieve a seamless connection between the ceramic and metal, preventing cracking or separation.

Glazing and Staining of Dental Ceramics

To create a natural look, restorations often go through a glazing and staining process, performed in dental lab porcelain ovens. This step enhances the appearance of restorations by providing a smooth, shiny finish and adding subtle colors that resemble the translucency and depth of natural teeth.

The ability to carry out precise staining is particularly valuable for technicians seeking to match the restoration perfectly to the patient’s natural dentition.

Benefits of Using Dental Porcelain Ovens

The advanced functionality of dental porcelain ovens offers a multitude of benefits that significantly enhance the efficiency and quality of dental lab outputs.

Precision in Temperature Control for Optimal Results

One of the standout advantages of dental firing ovens is their precision in

temperature control. This capability is vital for maintaining consistency across

multiple restorations, as each ceramic material requires specific temperatures

to achieve the desired hardness, translucency, and durability.

Consistency in Quality

Advanced dental porcelain ovens are designed with programmable firing cycles, which allow dental technicians to create high-quality restorations with repeatable results. With each cycle customized to the material used, the lab can reliably produce restorations that meet rigorous standards.

Improved Efficiency in Dental Lab Processes

Dental lab porcelain ovens streamline dental workflows, automating essential steps that would otherwise require extensive manual monitoring. Brother Furnace’s custom dental ceramics ovens are particularly beneficial for high-output labs, allowing them to manage increased demand without compromising on quality.

Enhanced Aesthetic Outcomes

These ovens support dental labs in achieving exceptional results that are visually indistinguishable from natural teeth. By offering capabilities such as vacuum firing and precise stain application, vacuum porcelain ovens enable technicians to create customized color gradients and surface textures.

Versatility in Handling a Range of Ceramic Materials

Modern dental porcelain ovens accommodate a variety of materials, from

traditional ceramics to high-end zirconia. This versatility makes them

indispensable in dental labs where a range of restoration types and materials

are required. With Brother Furnace’s high-temperature dental ovens, labs gain

the flexibility to experiment with diverse materials and expand their

restoration offerings.

Features to Consider When Purchasing a Dental Porcelain Oven

When selecting a dental porcelain oven, it’s essential to consider features that align with the needs and goals of the dental lab. Some of the most important features include:

Temperature Range and Control Accuracy

The best dental porcelain ovens come with extensive temperature ranges and fine-tuned control accuracy, ensuring they meet the specific requirements of materials like zirconia. Precise temperature control prevents overheating and guarantees that every restoration meets quality standards.

Chamber Size and Capacity

A large chamber allows for the processing of multiple restorations in a single cycle, an essential feature for high-demand labs. Brother Furnace offers models with varying chamber capacities, from small to large, providing options for both specialized and high-output operations.

Programmability and Preset Firing Cycles

Programmable porcelain ovens for dental restorations streamline workflow by

allowing technicians to save and apply preset cycles for different types of

restorations. This automation enables technicians to achieve uniform results

with minimal manual adjustments.

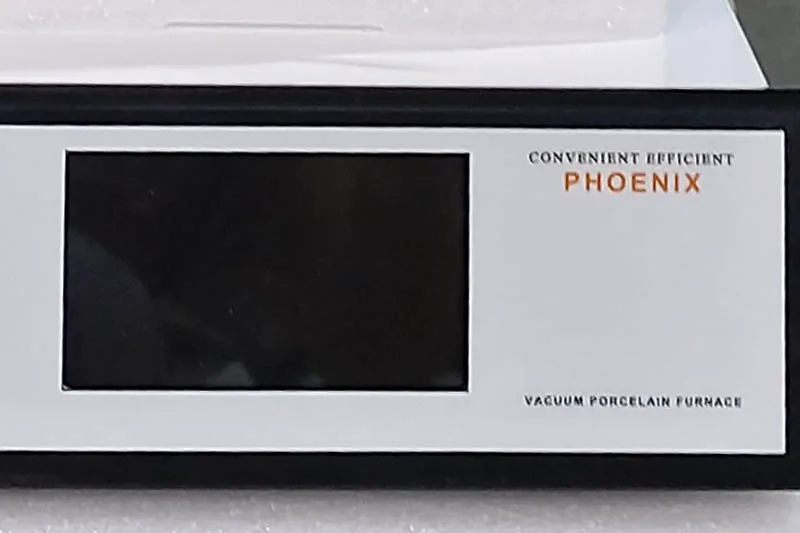

Vacuum Functionality

A vacuum porcelain oven is ideal for delicate restorations that require an oxygen-free environment to prevent oxidation. Vacuum capabilities help maintain the integrity of ceramic colors and prevent surface imperfections, enhancing the overall quality of the final product.

User Interface and Ease of Operation

A user-friendly interface is essential in busy labs. Advanced control panels and intuitive designs simplify operation, reducing the time required to train new staff and minimizing the risk of errors. Brother Furnace designs its ovens with ease of use in mind, helping labs maintain efficiency.

Energy Efficiency and Power Consumption

High energy efficiency reduces operational costs, especially for labs that run their ovens continuously.Brother Furnace’sdental porcelain ovens are optimized for low energy consumption, helping labs reduce their environmental footprint and improve profitability.

Maintenance and Care of Dental Porcelain Ovens

Proper maintenance of dental porcelain ovens is essential for extending their

lifespan and ensuring consistent quality in restorations.

Regular Cleaning Procedures

Regular cleaning of the oven chamber prevents contamination, which can affect the color and quality of restorations. Most dental lab porcelain ovens come with recommended cleaning routines to follow.

Calibration Requirements

Calibration ensures temperature settings remain accurate, a critical factor in achieving high-quality restorations. Consistent calibration of custom dental ceramics ovens guarantees uniform results across restorations.

Maintenance for Longevity

Routine maintenance, including checks on key components, is essential to avoid unexpected malfunctions and downtime. Brother Furnace provides comprehensive maintenance guidelines to help labs maximize the lifespan of their equipment.

Conclusion

The role of dental porcelain ovens in modern dentistry is integral, transforming raw materials into durable, lifelike restorations that enhance patient satisfaction and oral health.

Brother Furnace’s extensive range of high-temperature dental ovens is

designed to meet the diverse needs of today’s dental labs, combining precision,

efficiency, and ease of use to deliver high-quality results consistently.

Investing in well-designed dental porcelain ovens from Brother Furnace can significantly enhance a lab’s capabilities, ensuring that every restoration meets the highest standards for aesthetics and durability.

Brother Furnace looks forward to working with you!