The Mystery of Vacuum Technology in Dental Porcelain Furnace

In the field of modern restorative dentistry, porcelain restoration technology has now become one of the preferred methods for repairing tooth defects and improving the appearance of teeth for its excellent aesthetics, biocompatibility, and durability.

As the core equipment in the process of porcelain restoration, the performance and technological advancement of the porcelain furnace is directly related to the quality of the final restoration.

Brother Furnace's T-Run porcelain furnace has set a new benchmark for the dental industry with its unique vacuum technology, precise temperature control system, and user-friendly design.

In this article, we will analyze the vacuum technology of T-Run dental porcelain furnace from a professional point of view, and discuss how it becomes the key secret to improve the quality of porcelain.

About Porcelain Teeth and Porcelain Furnaces

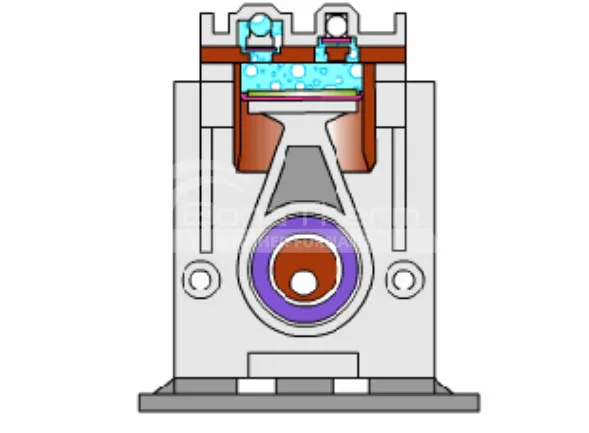

Porcelain furnace is the special equipment for the production of porcelain teeth.

With the improvement of living standards, porcelain teeth have been more and more accepted by oral patients.

Porcelain denture is a restorative method that uses porcelain on the outside of the tooth to achieve the color and function similar to that of a real tooth.

The surface of the denture is covered with a low-fusing porcelain powder similar to that of natural teeth, which is then sintered and fused in a high-temperature vacuum porcelain furnace. Porcelain dentures are then formed. Therefore, porcelain dentures have the strength and beauty of metal as well as a lifelike form.

The Significance of the Vacuum Environment for Porcelain Furnaces

The vacuum environment plays a crucial role in the porcelain restoration process.

Firstly, the vacuum environment effectively removes air bubbles from the interior and surface of the porcelain material, thereby reducing the loss of strength and aesthetics of the restoration due to the presence of air bubbles.

Secondly, vacuum conditions promote uniform fusion and tight bonding of the porcelain material. This not only improves the fit between the restoration and the abutment but also enhances the long-term stability of the restoration.

In addition, the vacuum also helps to reduce the oxidation reaction and protect the color stability and chemical stability of the porcelain material, ensuring that the restorations have a natural and long-lasting color.

It can be said that the quality of the vacuum technology directly affects the working ability of the dental porcelain furnace and the porcelain effect.

As a professional manufacturer of dental porcelain furnaces, Brother Furnace has won the trust and support of customers through advanced vacuum technology.

What kind of vacuum technology makes Brother Furnace’s customers so satisfied? The following will introduce you one by one.

Analysis of Vacuum Technology of T-Run Porcelain Furnace

1. High-efficiency Oil-free Vacuum Pump System

T-Run porcelain furnace adopts imported high-quality oil-free vacuum pump. This design not only avoids the oil pollution problems that may be brought by the traditional oil vacuum pump but also greatly improves the stability of the system and the convenience of maintenance.

Through the multi-layer filtration structure of the vacuum tube, the oil-free vacuum pump can effectively filter out the dust and particles in the air, to ensure that the air entering the furnace chamber is pure and free of impurities, further improving the environmental quality of the porcelain process.

2. High Precision Vacuum Control

Brother Furnace’s Porcelain Furnace can achieve a high vacuum of -98Kpa. The high-precision vacuum control means that during the porcelain baking process, the air inside the furnace chamber is quickly and completely expelled, creating a nearly perfect vacuum environment for the porcelain material.

This not only accelerates the melting process of the porcelain material but also ensures that the fused material adheres evenly and tightly to the abutment, thus improving the overall quality of the restoration.

Why the Vacuum Technology Could Improve the Quality of Porcelain

1. Bubble Removal is More Complete

Under the vacuum environment, the air bubbles inside and on the surface of the porcelain material can be eliminated quickly and completely.

This process not only reduces the effect of air bubbles on the strength of the restoration but also avoids the uneven surface and color problems caused by the presence of air bubbles, thus improving the aesthetics and durability of the restoration.

2. Melting is More Homogeneous

The vacuum environment promotes uniform melting of the porcelain material. During the melting process, the components of the material can be fully mixed and evenly distributed, avoiding the problem of localized high or low hardness caused by uneven melting.

This homogeneous melting state helps to form a more dense and homogeneous structure of the restoration, improving the overall performance of the restoration.

3. Better Sealing

The porcelain baking process under vacuum conditions helps to enhance the fit between the restoration and the abutment.

In the molten state, the porcelain material fits more closely to the surface of the abutment, forming a strong bond. This high degree of bonding not only improves the stability of the restoration but also reduces problems such as bacterial growth and dental caries caused by the presence of gaps.

4. Reduced Oxidation

The vacuum environment effectively reduces the oxidization of the porcelain materials during the heating process. Oxidation is one of the main causes of color change and deterioration of porcelain materials. Porcelain treatment under vacuum conditions can greatly reduce the incidence of oxidation reaction, thus protecting the color stability and chemical stability of porcelain materials, and ensuring that the restorations have a natural, long-lasting color.

The T-Run porcelain oven does not require special high-power grid support. It can be used on the electrical circuits within a domestic dwelling. This design not only reduces the cost of use but also increases the portability and applicability of the unit.

Other Advantages of the T-Run Porcelain Furnace

In addition to excellent vacuum technology, Brother Furnace’s T-Run porcelain furnace also has several other advantages, which together constitute its comprehensive ability to enhance the quality of porcelain.

1. High-quality Quartz Tube Furnace Chamber

T-Run porcelain furnace adopts high-quality quartz tubes as the furnace chamber material, which not only has excellent high-temperature resistance and chemical stability but also can effectively reduce the loss of heat radiation and uneven heat conduction.

This design ensures the uniformity and stability of the temperature in the furnace chamber, providing a good thermal environment for the porcelain baking process.

2. Use of Kanthal Fe-Cr-Al-Mo Wire Heating Element

The resistance heating element is one of the key components of this porcelain furnace. T-Run dental porcelain furnace uses the famous Kanthal Fe-Cr-Al-Mo wire heating element, which is known for its high efficiency, stability, and durability.

During the porcelain process, the Kanthal Fe-Cr-Al-Mo wire heating element can quickly and evenly generate heat to ensure that the porcelain material reaches the desired melting temperature within a predetermined period of time.

3. 30-Segment Programmable and Auto Control

Equipped with 30-segment programmable and auto control system, users can set different heating procedures and parameters according to the actual needs to meet the needs of different porcelain materials and restorations. In addition, the equipment also stores 100 commonly used procedures (optional expansion to 500), which is convenient for users to quickly call and modify.

4. Convenient Operation Interface

The dental porcelain furnace has a 10-inch large screen. The operation interface is clear and intuitive. Users can easily set up and monitor the porcelain process.

5. Low Power and High Performance

T-Run porcelain furnace does not require special high power grid support. It can be used in a domestic house. This design not only reduces the cost of use but also improves the portability and applicability of the equipment.

Summary

With its excellent vacuum technology, precise temperature control system and user-friendly design, the T-Run porcelain furnace shows strong competitiveness and wide application prospects in the field of dental restoration. Its highly efficient vacuum environment, uniform melting effect and high tightness of the restorations provide a strong guarantee for the improvement of porcelain quality.

In the future, with the continuous progress of technology and market expansion, T-Run porcelain furnace will certainly play a more important role in the field of dental restoration. Brother Furnace hopes that T-Run dental porcelain furnace will bring more patients beautiful and healthy smiles.